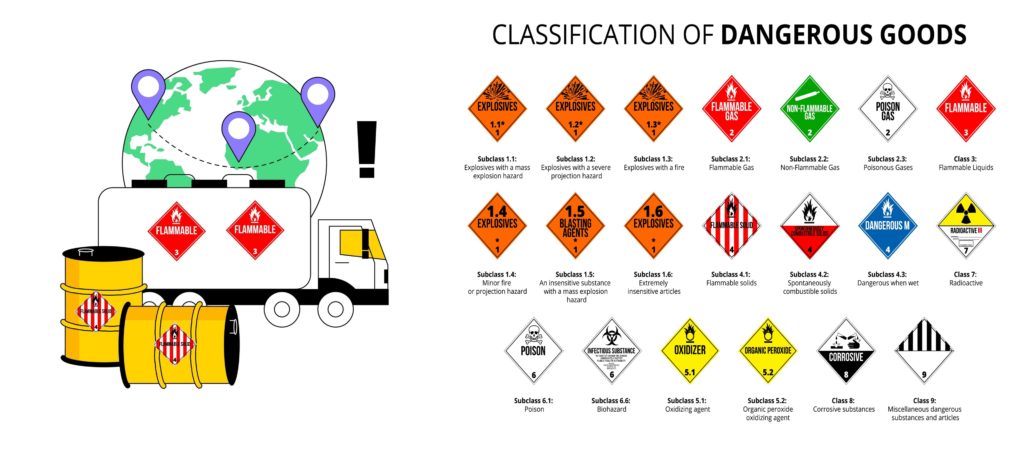

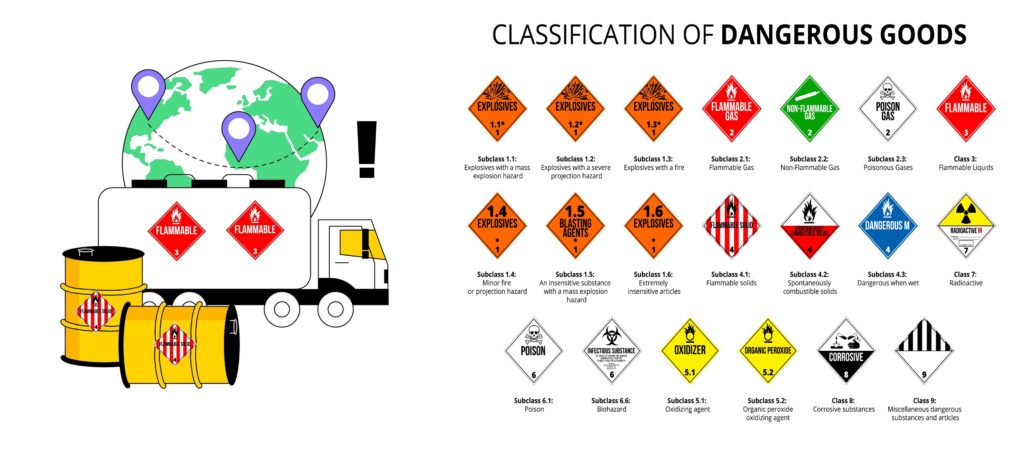

In today’s globalized world, the safe transportation of hazardous goods is of utmost importance. Whether it’s chemicals, pharmaceuticals, or other dangerous substances, ensuring their secure transit from one location to another is crucial to prevent accidents, protect human health, and safeguard the environment. This is where United Nations (UN) approved packaging comes into play. In this blog post, we will delve into the different types of UN approved packaging and understand why they are essential for the safe handling and transportation of hazardous materials.

What is UN Approved Packaging?

UN approved packaging refers to a specific type of packaging that has been rigorously tested and certified by the United Nations to meet international standards for the safe transport of hazardous goods. These packages are designed to withstand the rigors of transportation, including rough handling, temperature changes, and potential impacts, without compromising the integrity of the contents or posing a risk to people or the environment.

Categories of UN Approved Packaging

UN approved packaging can be broadly categorized into several types based on the nature of the hazardous goods being transported. Here are some common categories:

- Drums: Drums are cylindrical containers made of metal, plastic, or fiber. They come in various sizes and are commonly used for liquids, powders, and granules. UN approved drums undergo stringent testing to ensure they can withstand stacking, dropping, and vibration without leaking or rupturing.

- IBCs (Intermediate Bulk Containers): IBCs are large, reusable containers typically made of plastic or composite materials. They offer a flexible and cost-effective solution for bulk storage and transportation of hazardous goods. IBCs must meet strict design and construction standards to qualify as UN approved.

- Jerrycans: Jerrycans are portable, usually plastic or metal cans equipped with a handle and a screw cap. They are ideal for smaller quantities of hazardous liquids. Like drums, jerrycans are tested for durability and leak resistance.

- Plastic Bottles and Cans: For non-corrosive liquids and solids, UN approved plastic bottles and cans provide a lightweight and shatterproof option. These containers must comply with specific design criteria to ensure they can safely contain hazardous substances during transport.

- Glass Bottles: While less common due to their fragility, some hazardous materials may still be transported in specially designed UN approved glass bottles. These bottles are manufactured to high strength and equipped with protective features to minimize breakage risks.

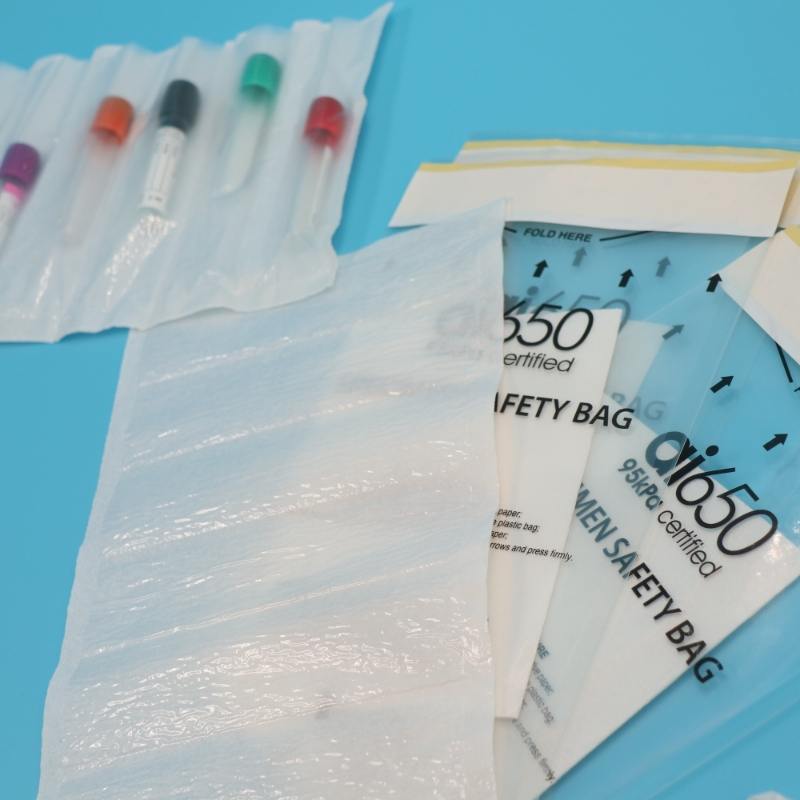

- Combination Packaging: This category includes combinations of inner receptacles (such as glass or plastic bottles) and outer packaging (like cardboard boxes or wooden crates). The combination must be tested as a whole to ensure it provides adequate protection for the hazardous goods.

- Pressure Relief Packaging: For certain substances that generate gas under temperature fluctuations or other conditions, UN approved pressure relief packaging incorporates mechanisms to vent the gas safely while maintaining the integrity of the container.

Why Use UN Approved Packaging?

Using UN approved packaging offers several benefits:

- Safety: It ensures the safe containment and transport of hazardous goods, reducing the risk of accidents and spills.

- Compliance: Many countries have regulations that mandate the use of UN approved packaging for the transportation of hazardous materials. Compliance avoids legal issues and potential fines.

- Peace of Mind: Knowing that your hazardous goods are packaged according to international standards provides confidence to all parties involved in the supply chain.

- Efficiency: Properly packaged goods are less likely to be damaged in transit, reducing waste and improving overall logistics efficiency.