Introduction: The Criticality of Compliant Biological Sample Transport

The global landscape of healthcare and scientific research increasingly relies on the efficient and safe transportation of biological and diagnostic samples. As medical advancements accelerate and diagnostic capabilities expand, the volume and frequency of these shipments continue to rise. This logistical challenge is underscored by a paramount concern: ensuring the safety of personnel, the public, and the environment. The movement of biological materials is not merely a matter of logistics; it is a critical public health imperative that demands meticulous adherence to established international safety protocols.

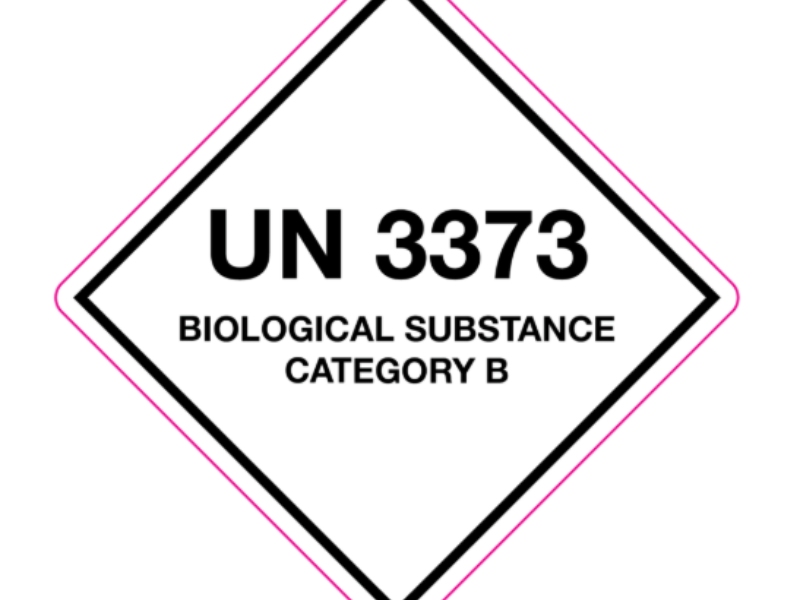

At the heart of this regulatory framework lies UN 3373, the internationally recognized classification for “Biological Substance, Category B”. This designation governs the transport of human or animal materials intended for vital purposes such as diagnosis, research, investigational activities, disease treatment, or prevention. While these substances are categorized as presenting a relatively low risk in the event of a release, their proper handling and packaging are non-negotiable.

Strict adherence to international regulations, particularly those set forth by authoritative bodies like the International Air Transport Association (IATA), the European Agreement concerning the International Carriage of Dangerous Goods by Road (ADR), and the U.S. Department of Transportation (DOT), is not merely a legal obligation; it is a fundamental commitment to safety. Compliance ensures that these potentially hazardous materials are managed with the utmost care, preventing incidents that could lead to exposure, contamination, or disruption of critical medical and research supply chains. Failure to comply can result in severe consequences, including substantial financial penalties, shipment delays, and significant damage to an organization’s reputation.

This report aims to provide a comprehensive and authoritative guide to the specific regulatory requirements for the UN 3373 diamond marking, with a particular focus on its minimum dimensions. Furthermore, it will illustrate how compliant packaging solutions, exemplified by the ai650 specimen bag, are integral to achieving and maintaining this crucial regulatory adherence, offering both safety and peace of mind to shippers.

Demystifying UN 3373: Understanding Category B Biological Substances

To ensure the safe transport of biological materials, it is essential to understand their classification. UN 3373 specifically defines “Biological Substance, Category B” as infectious substances that do not meet the criteria for inclusion in Category A. This means they are not in a form generally capable of causing permanent disability or life-threatening or fatal disease in otherwise healthy humans or animals upon exposure. This distinction is crucial for determining the appropriate level of packaging and handling required.

Common examples of materials typically classified under UN 3373 include a wide array of human or animal specimens transported for diagnostic or investigational purposes. These can encompass blood and its components, urine, tissue, tissue fluids, body parts, and excreta. Such samples are routinely transported for various medical and scientific objectives, from routine diagnostic tests to complex research studies.

A critical differentiation must be made between Category B (UN 3373) and Category A (UN 2814 or UN 2900) infectious substances. Category A substances represent a significantly higher risk, being capable of causing permanent disability, life-threatening, or fatal disease if exposure occurs. This higher risk profile necessitates vastly more stringent packaging and labeling requirements for Category A materials, often involving UN-type approved packaging, which is not strictly mandated for Category B substances as long as they meet performance standards. This tiered, risk-based approach to hazardous materials transport regulations ensures that the level of protective measures is proportional to the perceived hazard, streamlining logistics for lower-risk samples while maintaining robust safety standards.

It is paramount to recognize that the responsibility for correctly classifying any infectious substance rests solely with the shipper. This places a significant onus on consignors to possess thorough knowledge of the regulations and to exercise due diligence in determining the appropriate classification before preparing any shipment. Misclassification can lead to severe penalties and compromise safety protocols.

The Triple Packaging System: Adhering to Packing Instruction 650 (P650)

All shipments of UN 3373 Biological Substance, Category B, must strictly comply with Packing Instruction 650 (P650), a universally adopted standard across international transport regulations including IATA, ADR, and DOT. This instruction mandates a robust triple packaging system designed to ensure the integrity and containment of biological samples under normal transport conditions, safeguarding against potential loss of contents due to vibrations, temperature fluctuations, humidity changes, or pressure variations.

The P650 instruction specifies three mandatory components that must work in concert to form a secure system:

- Primary Receptacle(s): This innermost container directly holds the biological specimen. It must be leak-proof for liquid substances, with a maximum capacity of 1 Litre per primary receptacle. For solid substances, it must be sift-proof and its contents must not exceed the outer packaging weight limit. If multiple or fragile primary receptacles are used, they must be individually wrapped or separated within the secondary packaging to prevent contact and breakage during transit.

- Secondary Packaging: This intermediate layer encloses the primary receptacle(s). It must also be leak-proof for liquids or sift-proof for solids. A critical requirement for liquid substances is the inclusion of sufficient absorbent material placed between the primary and secondary packaging. This material must be capable of absorbing the entire contents of all primary receptacles in case of a leak, thereby preventing the contents from compromising the integrity of the secondary or outer packaging. Importantly, either the primary or the secondary packaging must be capable of withstanding, without leakage, an internal pressure differential of not less than 95 kPa. This pressure resistance is vital to ensure containment under varying atmospheric conditions, particularly during air transport.

- Rigid Outer Packaging: This outermost container provides robust physical protection for the entire system. It must be of rigid construction, typically made from materials such as corrugated fiberboard, plastic, or metal, and be strong enough to withstand the normal rigors of transport, including handling shocks and changes in environmental conditions. The outer packaging must not contain more than 4 Litres of liquid or 4 kg of solids per package, excluding the weight or volume of coolants like ice, dry ice, or liquid nitrogen when used to maintain temperature.

A fundamental performance requirement for the entire triple packaging system is its ability to successfully pass a 1.2-meter (approximately 4-foot) drop test. Following this test, there must be no leakage from the primary receptacle(s), and the contents must remain protected by the absorbent material within the secondary packaging. This test simulates real-world handling stresses and ensures the system’s resilience.

Crucially, at least one surface of the rigid outer packaging must have a minimum dimension of 100 mm × 100 mm (approximately 4 inches × 4 inches). This specific dimension is vital for ensuring adequate space for all necessary markings and labels to be clearly visible and legible, a requirement that directly contributes to safety and compliance.

The consistent emphasis across various regulatory documents on the three distinct layers of primary, secondary, and rigid outer packaging, coupled with specific performance requirements like leak-proofness, absorbent material, 95kPa pressure resistance, and the 1.2m drop test for the completed package, reveals a deeper underlying regulatory philosophy. This approach is not merely about containing the substance; it is about building in multiple layers of protection and redundancy. This layered design is a deliberate strategy for risk mitigation. It acknowledges that individual components can fail during transit due to unforeseen impacts, temperature fluctuations, or pressure changes. If the primary receptacle fails, the absorbent material and secondary packaging are designed to contain the spill, preventing external contamination. If the secondary packaging is compromised, the rigid outer packaging provides a final, robust barrier. The 95kPa pressure resistance anticipates extreme conditions like air transport, where significant pressure differentials can occur. The 1.2m drop test is a practical simulation of real-world handling stresses, ensuring the entire system can withstand typical abuses without compromising containment. This systematic approach minimizes the risk of environmental contamination or exposure to personnel, even in the event of an internal packaging failure. It is a proactive safety measure, anticipating potential points of failure and building in safeguards. This multi-layered defense mechanism is a fundamental principle in hazardous materials transport, ensuring that safety is maintained even under adverse conditions. It underscores that compliance isn’t just about meeting minimums for each component in isolation but ensuring the entire system functions as a cohesive, resilient unit to prevent any loss of contents. This systemic view also implies that manufacturers of individual components must design their products to contribute to the overall system’s integrity and performance, not just their standalone features.

The UN 3373 Diamond Mark: Dimensions and Display Requirements

The UN 3373 diamond mark serves as the primary visual identifier for packages containing Category B biological substances. Its clear and unambiguous display is crucial for rapid identification by transport personnel, enabling them to apply appropriate handling protocols and emergency procedures without delay.

The precise, legally mandated minimum dimensions for the UN 3373 diamond mark are remarkably consistent across international regulations (IATA, ADR, ICAO, DOT):

- Shape: The mark must be in the form of a square set at an angle of 45° (i.e., diamond-shaped).

- Side Length: Each side of the diamond must have a minimum length of 50 mm (which equates to approximately 2 inches).

- Line Width: The width of the line forming the diamond’s border must be at least 2 mm thick.

- Letter and Number Height: All letters and numbers within or adjacent to the mark (e.g., “UN 3373” and the Proper Shipping Name) must be at least 6 mm high.

| Feature | Requirement |

| Shape | Square set at an angle of 45° (diamond-shaped) |

| Minimum Side Length | At least 50 mm (2 inches) |

| Minimum Line Width | At least 2 mm |

| Minimum Letter/Number Height | At least 6 mm |

| Background Requirement | Contrasting color to the package surface |

| Specific Symbol/Number Exclusion | Does NOT contain the biohazard sign or the number “6” |

The display requirements for the UN 3373 diamond mark are equally stringent. It must be prominently displayed on the external surface of the rigid outer packaging. For air shipments, it is typically required on one of the four external sides, ensuring visibility from multiple angles. The mark must be clearly visible and legible, placed on a background of a contrasting color to ensure maximum readability under various lighting conditions and distances. Regulations offer flexibility in how the mark is applied: it can be handwritten or drawn directly onto the outer packaging (provided all specified dimensions are strictly adhered to), applied via pre-printed sticky labels, or pre-printed directly onto the packaging itself.

A crucial clarification, often overlooked, is that for Category B infectious substances (UN 3373), this specific diamond mark does not contain the universal biohazard symbol or the number “6”. This distinction is vital for accurate hazard communication, as the Class 6.2 label (which includes the biohazard symbol and the number ‘6’) is specifically reserved for higher-risk Category A substances. This precise differentiation prevents misclassification and ensures that the communicated risk aligns exactly with the actual hazard level, guiding appropriate handling and emergency response.

The research consistently differentiates between the “UN 3373 mark” (50x50mm, specific to Category B) and general “Danger labels” (often 100x100mm, with some reducibility). This distinction is paramount for accurate hazard communication. The specific 50x50mm UN 3373 diamond is a tailored visual identifier for a substance with a lower risk profile (Category B) compared to Category A. A general Class 6.2 infectious substance label (which would include the biohazard symbol and the number ‘6’) would imply a higher, Category A risk. Mislabeling could lead to inappropriate emergency response, unnecessary alarm, or, conversely, desensitization to a true Category A hazard if the distinction is not clear. The smaller size of the UN3373 mark also reflects its specific, less severe hazard profile, allowing for more efficient use of package space while still ensuring visibility. This highlights the highly granular and precise nature of dangerous goods regulations. Every detail, including size, line thickness, and omitted symbols, serves a specific purpose in communicating the exact level and type of hazard. Compliance requires not just applying a diamond, but applying the correct diamond with the correct specifications to avoid regulatory violations and ensure appropriate handling protocols are followed. This precision is a cornerstone of safety in hazardous materials transport.

Beyond the Diamond: Other Essential Markings for UN 3373 Packages

While the UN 3373 diamond mark is central to compliance, it is only one component of a comprehensive set of markings required on packages containing Category B biological substances. Adherence to all these requirements is critical for ensuring safety and avoiding regulatory penalties.

Proper Shipping Name: The full proper shipping name, “BIOLOGICAL SUBSTANCE, CATEGORY B,” must be clearly and durably marked on the external surface of the outer packaging. This text should be located adjacent to the diamond-shaped mark and must be in letters at least 6 mm high. In some contexts, “Diagnostic specimen” or “Clinical specimen” may also be acceptable as the proper shipping name.

Responsible Person’s Information: For air shipments, a critical safety requirement is the inclusion of the name and a 24-hour, uninterrupted emergency contact telephone number of a responsible person. This information must be clearly listed on the outside of the package, ensuring that someone can be reached about the package while it is in transit, particularly in emergency situations.

Consignor and Consignee Information: The names and complete addresses of both the consignor (sender) and consignee (receiver) are mandatory. This includes emergency contact details (name and telephone number) for both the origin and destination points. While often placed on the same surface for convenience, regulations may allow them to appear on different surfaces of the package.

Orientation Arrows: For packages containing liquid substances, “Package Orientation” labels (also known as “This Way Up” or “Orientation Harrows”) are required. These labels must be at least 74 x 105 mm in size, feature two black or red arrows on a white or contrasting background, and must be affixed or pre-printed on at least two opposite sides of the package. Their purpose is to clearly indicate the proper upright position for the primary receptacle(s) during transport, preventing spillage. It is worth noting that orientation arrows are generally not required for packages containing Class 6.2 infectious substances in primary receptacles of not more than 50 ml.

Overpack Marking: When multiple compliant packages are consolidated into an overpack (an outer container used for convenience or to facilitate refrigeration), specific marking rules apply. The overpack must be clearly marked with the word “OVERPACK,” and all required markings from the inner packages must either be clearly visible through the overpack or reproduced on its external surface.

Class 9 Hazard Label (for Dry Ice): If dry ice is utilized as a refrigerant to maintain temperature-sensitive biological samples, a separate Class 9 – Miscellaneous dangerous goods hazard label must be affixed to the outer packaging. This label is also diamond-shaped, but it is larger, measuring at least 10 cm x 10 cm (100mm x 100mm), with black text on a white background, and a 5mm line running parallel inside its edge. This label is distinct from the UN 3373 mark and indicates a different type of hazard associated with the coolant.

Itemized List of Contents: An itemized list detailing the contents of the package must be enclosed between the secondary packaging and the rigid outer packaging. This list is crucial for customs, emergency responders, and recipients, providing essential information about the package’s contents.

The mandatory minimum outer packaging dimension of 100mm x 100mm is directly related to ensuring the legibility of these numerous markings. This consistent requirement across regulations ensures that there is sufficient “real estate” on the package’s surface to accommodate the 50x50mm diamond mark, the 6mm high text for the Proper Shipping Name, emergency contact details, and potentially other necessary labels like orientation arrows or overpack indicators, without overlapping or compromising their legibility. A package that is too small would make it difficult, if not impossible, to place all required markings and labels on a single, flat surface without overlapping or compromising legibility. This would lead to non-compliance and potential mishandling. This minimum dimension is a proactive measure to ensure that critical safety information is always clear and immediately identifiable by anyone handling the package, especially during rapid transit or in emergency situations. This highlights that regulatory compliance is not just about meeting individual component specifications but about ensuring the overall package design facilitates the clear and unambiguous communication of hazard information. The physical dimensions of the outer packaging are a critical enabler for the effective application and visibility of all required markings, thereby directly contributing to the broader safety ecosystem of hazardous goods transport.

The ai650 Specimen Bag: A Key Component for UN 3373 Compliance

In the complex landscape of UN 3373 biological substance transport, choosing the right packaging components is paramount for ensuring compliance and safety. The ai650 specimen bag is a purpose-built solution, specifically engineered to meet the rigorous demands and complex regulatory requirements of Category B biological substance transport.

The ai650 bag seamlessly integrates into the P650 triple packaging system, primarily functioning as a highly compliant secondary packaging component. Its robust, leak-proof construction makes it an ideal choice for securely containing primary receptacles and the necessary absorbent material, forming a critical protective layer within the overall system.

The design and features of the ai650 bag are meticulously crafted to ensure both compliance and practical utility:

- Certified Compliance: The ai650 bag boasts full certification and adherence to UN3373 Category B and P650 standards. It is explicitly designed to meet the stringent requirements for both road and international shipments, including compliance with IATA and DOT regulations for biological shipments. This certification provides shippers with confidence that a key component of their packaging system meets global regulatory benchmarks.

- Durable & Leak-Proof Construction: Manufactured from a robust, puncture-resistant Co-Ex LDPE material (60mu grade), the ai650 bag is engineered to prevent leaks and protect the contents from external contamination. This durable construction ensures the integrity and safety of the specimens throughout the entire transportation process, even under normal handling conditions.

- Tamper-Evident Design: The bag incorporates tamper-proof closures and secure seals. This feature provides an added layer of security, ensuring that the shipment arrives intact and untampered with. It offers crucial traceability and peace of mind, particularly for sensitive diagnostic or research samples where maintaining the chain of custody is paramount.

- Clear Labeling & Easy Handling: Designed with ample space, the ai650 bag facilitates clear and accurate labeling. This feature ensures that the bag itself can be easily identified and handled by couriers and recipients, streamlining the logistical process while adhering to regulatory requirements for internal package identification.

- Convenient Sizes: With specific dimensions of 7 x 9.4″ (180 x 240mm), the ai650 bag is strategically sized to comfortably accommodate various types of primary receptacles and sufficient absorbent materials. Its dimensions are also optimally suited to fit within a wide range of compliant rigid outer packaging options that meet the mandatory 100mm x 100mm minimum dimension, ensuring system-wide compatibility.

- Sustainable & Eco-Friendly: Beyond its compliance and functional features, the ai650 bag demonstrates a commitment to environmental responsibility. It is 100% recyclable and manufactured with a minimum of 30% post-consumer waste (PCW). This aligns with evolving industry trends towards sustainability and allows organizations to enhance their environmental footprint.

The ai650 bag is more than just a container; it is a pre-engineered solution that significantly simplifies the compliance burden for shippers. By providing a certified secondary packaging component, it removes a major variable in the complex triple packaging system, thereby reducing the likelihood of errors and ensuring a higher level of safety. The tamper-evident feature adds a crucial layer of security, which is vital for maintaining the integrity and chain of custody of sensitive diagnostic or research samples. This goes beyond basic physical containment to address crucial operational and ethical considerations. Furthermore, the integration of sustainable materials demonstrates a proactive approach to environmental responsibility, aligning the product with evolving industry expectations and providing a competitive advantage. This holistic design indicates that the product is developed not just to meet minimum regulatory standards but to exceed them in terms of practical utility, security, and modern values. This product exemplifies how manufacturers can play a pivotal role in enhancing the overall safety and efficiency of the hazardous goods transport ecosystem. By offering pre-compliant, feature-rich components, they empower their customers to achieve regulatory adherence more easily, significantly reduce operational risks (such as mishandling or contamination), and even enhance their own brand image through responsible and sustainable practices. It shifts the focus for shippers from simply understanding “what to do” to efficiently and reliably executing “how to do it effectively and responsibly.”